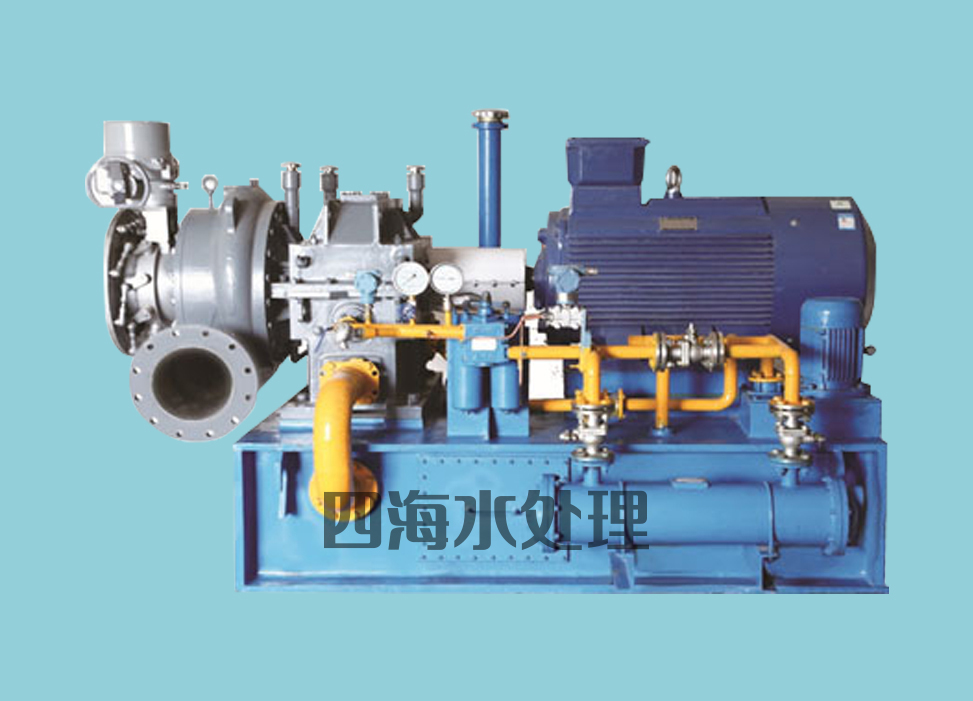

Single-stage high-speed centrifugal blower

The single-stage high-speed blowers produced by Shandong Sihai Water Treatment Equipment Co., Ltd. are mainly divided into two series, D and GS, which respectively adopt two structures of high-efficiency motor + speed-increasing box and high-speed motor direct drive, each with its own characteristics. All series of impellers and volutes are designed, analyzed, and simulated by the United States NREC professional software, with efficient aerodynamic performance and ultra-high stability and reliability.

1. Advanced impeller profile and high efficiency

The impeller is designed with ternary flow theory. After applying 3D software modeling, the performance of the blower is verified by computer flow analysis technology, so that the single-stage high-speed centrifugal blower has a variable efficiency of up to 85%.

2. The flow adjustment range is wide and can be applied to a variety of working conditions

The fan adopts axial intake guide vane and diffuser adjustment device, and the flow adjustment range is 60% to 110% of the rated flow, which makes it more efficient to operate under non-rated operating conditions. Equipped with anti-surge device can effectively avoid blower surge.

3. The fan has a compact structure and a small volume

The assembled integral structure is adopted. The blower body is assembled on the casing of the gear speed increase box. The lubricating oil system, motor and gear speed increase box are compactly arranged on a common base. The commissioning cycle is short.

4. After the rotor is strictly balanced, the vibration is small, the reliability is high, and the overall noise is low

The impeller is made of forged aluminum alloy and finished by a machining center. The rotor has a small rotational inertia, and the unit has a short start-up and shutdown time. There is no need for a high-level oil tank and an accumulator. Compared with multi-stage centrifugal blowers of the same flow rate and pressure, it has low energy consumption, light weight and small footprint.

5. The fan structure is advanced and reasonable, with few wearing parts, easy installation, operation and maintenance

Bearing vibration temperature rise, fan inlet and outlet pressure, temperature, anti-surge control, start interlock protection, fault alarm, lubrication system oil pressure, oil temperature control, etc. are all programmable logic control, so that the whole machine operation is monitored in real time . The machine has no wearing parts, and daily maintenance is convenient.

Phone

Phone Message

Message